Services we perform

NGG’s firm belief is that Pre-Project Planning, Resource Loaded Schedules, Control Budgets, Quality Plans, and Safety Plans are critical components of any successful project. For this reason NGG dedicates a full time Project Management Professional to each of its projects. Our project managers are supported by back office functions such as drafting, procurement and accounting. These support systems provided to the project managers allow them to focus on planning and delivering successful projects for our customers.

Design Build & Pre-Construction

We work with the Architect, Owner and General Contractor early in the design phase of the project to assist with the design of the enclosure system. There are many engineering and design decisions to make and we are here to help. Most Architects and General Contractors are not facade experts. That is why they reach out to us to help with reviews, engineering, design and product selection. Through this process when the construction drawings are finalized, there is a system in place that is not only constructible but will perform in accordance with the requirements of the project, while keeping the aesthetic design in place. This phase saves time and money when it comes time to fabricate and install. We can also draw and engineer our systems in-house, producing both shop and fabrication drawings for project submittals and shop fabrication and field installation. Our in-house capabilities facilitate collaborative design and quick response during this early but very important phase of the project life cycle.

Other design services include:

Project Management

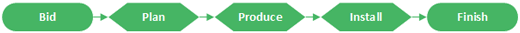

NGG provides professional project execution services to enable the customer to achieve a successful outcome. The NGG project execution philosophy is to represent the best interests of the customer and their agent at all times through the professional performance of NGG’s Project Team. NGG uses a systematic approach to project execution. This approach is based on close cooperation between the customer, agent and the NGG Project Team during the major phases of a project, which are:

To meet the NGG goals of striving for excellence, meeting or exceeding customers' requirements, working safely, empowering associates, and becoming the leader in our industry, NGG has developed our own project execution procedures. These processes, policies, and procedures used for all NGG projects cover:

- Project Execution Planning (PEP)

- Scheduling

- Project Controls and Reporting

- Estimating

- Quality

- Field Procedures and Installation

- Safety

- Project Turnover

Manufacturing

Our process focus allows NGG to provide quality products in a controlled factory setting resulting in faster completion times and minimization of costs. The process begins in our factory where all materials are received, cut and fabricated. The fabricated components are then assembled into units, glazed and sealed. Next, shadow boxes, insulation and back pans are installed (if they are required). Finally, the finished units are loaded onto trucks and transported to the jobsite. Curtain wall units are picked off the truck by use of a crane and set on pre-installed anchors.

Benefits of this Approach:

- Higher quality seals installed in a factory setting.

- Quality control procedures and documentation on each panel produced.

- Minimal negative schedule impacts due to unpredictable field conditions and weather.

- Small lay down footprint on the site; panels are installed as delivered.

- Minimal impact on other trades due to little or no space required on the floor.

- Speed of installation and enclosure.

Installation

The quality of installation is critical to the final outcome of the project:

- NGG provides full time supervision of its crew with a non-working superintendent on every project

- Productivity - NGG actively manages and tracks field productivity through the use of resource curves and productivity tools

- NGG sources labor locally to improve productivity

- NGG develops a labor supply plan for each project

- Turnover is sequenced by system, unit, or area

- Quality is checked and recorded on quality forms daily during the installation process

- Safety risks and hazardous operations are identified and proactively managed